PPGL Coil

Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

- Commodity name: PPGL Coil

- Product Description

-

- PRODUCT DESCRIPTION

PPGI is galvanized color plate, PPGL is galvanized color plate, both are color plates, the substrates are different, one is galvanized structure, the other is galvanized structure, the substrate is different, which determines the difference in performance.

Advantages: It not only has the mechanical strength and easy forming properties of steel plates, but also has good decorative properties and corrosion resistance of organic materials. The coating has strong adhesion and can keep the color fresh for a long time. Application: Widely used in various fields such as construction, home appliances, furniture, public facilities and transportation.

Product Name Color Coated Coil Thickness 0.12mm-2.0mm Width 600mm-1600mm or customized Material G550 CGCC SGCC DX51D+Z Surface Coating Thickness 10μm-30μm Back Coating Thickness 5μm-20μm Standard AISI ASTM JIS DIN BS EN GB Substrate Material Cold rolling, hot-dip galvanizing, galvalume, galvanized aluminum-magnesium, electro-galvanizing Coating Structure Two floors on the front and one floor on the back,Two floors on the front and two floors on the back Surface State EEmbossed, printed, mesh, suede, pearlescent, scratch-resistant Color Type Red series,Orange series,Green series,Blue series,Gray series,Brown-black series,White series,Metal series Topcoat Function self-cleaning,antistatic,antibacterial,thermal,insulation Surface Ordinary chemical pretreatment, chromium-free chemical pretreatment Application Construction industry, automobile manufacturing, non-ferrous metals, electric power, coal mining, light industry, medicine, food, etc.

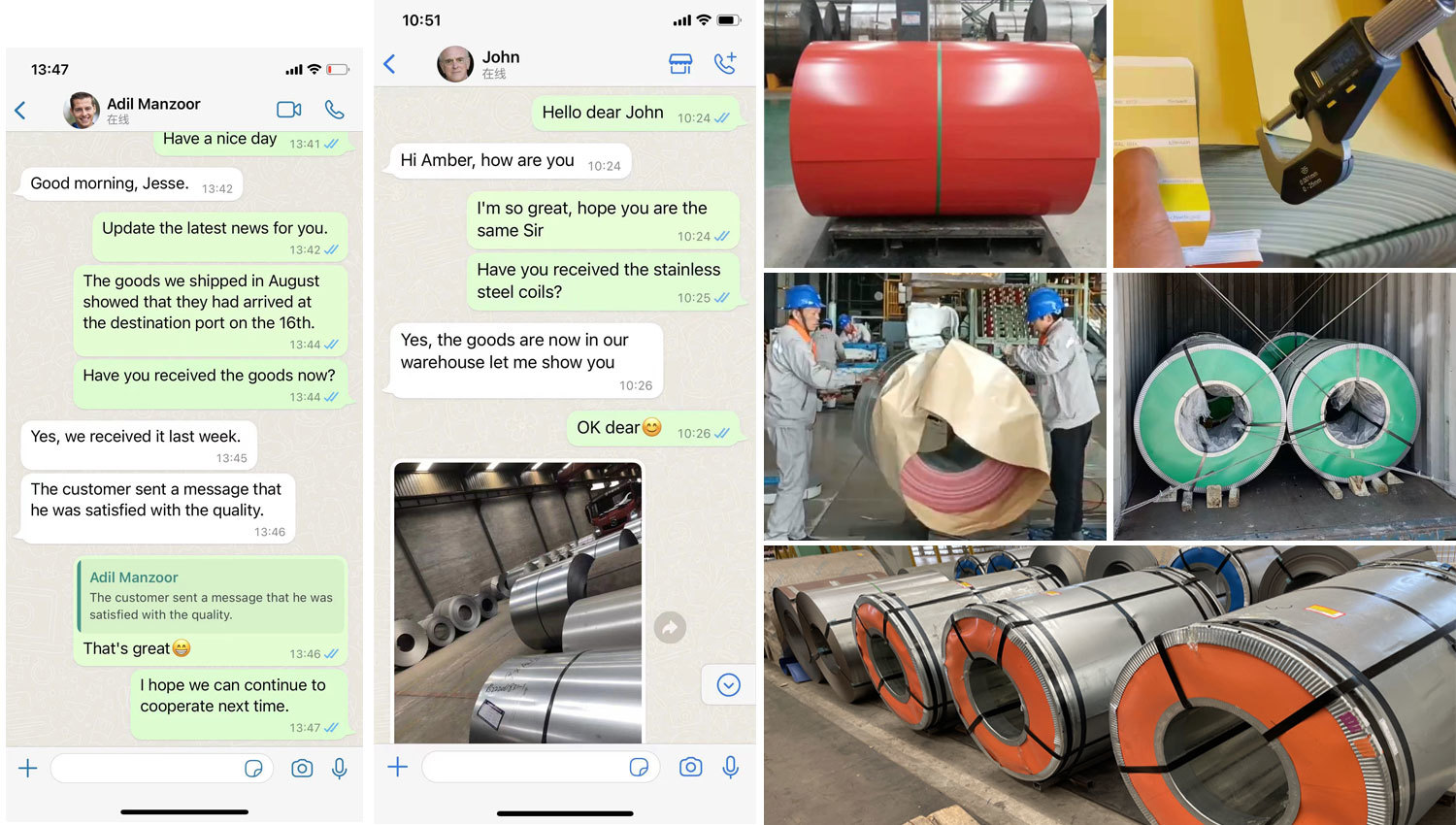

Customer feedback and packaging and transportation